Is Cordwood Masonry "Green?"

by Rob Roy

I write a Q and A column about cordwood masonry for Kelly Hart's excellent Green Home Building website, www.greenhomebuilding.com Recently, the following question came in, and I got so caught up in it that I called BackHome magazine editor Richard Freudenberger to see if he'd like to see it expanded into an article. So here it is.

Question from Anonymous: How can you consider cordwood as "green" when it uses so much cement in the mortar?

Great question, one I'm glad to have the opportunity to answer. First, I guess we have to come up with some sort of definition about what "green" means, with regard to building. My own view is that a green building must have a significant degree of the following elements: sustainability, leaving little impact on the planet, energy-efficiency in the making (often referred to as "embodied energy") and energy-efficiency in performance (fuel efficiency for heating and cooling.) A closely related element would be that the building is healthy, particularly not chemically toxic. There may be other elements or considerations, but these are the ones that come to mind for me. So how does cordwood masonry stack up? (Oops, that was unintentional; I do not mean for this to be a how-to article!)

Sustainability: Cordwood masonry "stacks up" very well here. With hybrid poplars, and other fast-growing woods, you can grow your own house in 5 to 7 years. And these light-weight woods are good with respect to both their insulation value and their stability (expansion and shrinkage.) A related consideration is that cordwood masonry can make use of "scrap wood" which is unsuitable as firewood, or for the sawmill: curved logs, hollow logs, shorts, driftwood, logging slash, ends and pieces. When cut into 8" to 16" pieces, you can get a lot of log-ends from "waste" woods. I clean up the yard at a local log home manufacturer every now and again, and get nice dry white cedar pieces - 12" to 60" long - for free. I haven't paid for cordwood in years. Try any company that makes wood products: Log cabin builders, sawmills, furniture makers, fence post makers, landscapers or tree clearing companies. The amount of wood that gets tipped into the landfill is both a shame and a minor environmental disaster. Surely it is green to make good use of this waste.

Sustainability: Cordwood masonry "stacks up" very well here. With hybrid poplars, and other fast-growing woods, you can grow your own house in 5 to 7 years. And these light-weight woods are good with respect to both their insulation value and their stability (expansion and shrinkage.) A related consideration is that cordwood masonry can make use of "scrap wood" which is unsuitable as firewood, or for the sawmill: curved logs, hollow logs, shorts, driftwood, logging slash, ends and pieces. When cut into 8" to 16" pieces, you can get a lot of log-ends from "waste" woods. I clean up the yard at a local log home manufacturer every now and again, and get nice dry white cedar pieces - 12" to 60" long - for free. I haven't paid for cordwood in years. Try any company that makes wood products: Log cabin builders, sawmills, furniture makers, fence post makers, landscapers or tree clearing companies. The amount of wood that gets tipped into the landfill is both a shame and a minor environmental disaster. Surely it is green to make good use of this waste.

Extend yourself when it comes to creative cordwood procurement. Nothing ventured, nothing gained. You'll be amazed with the results.

Leaving little impact on the planet: Eventually, all our structures must return to the earth from which they came. Even the pyramids are not proof; eventually they will erode into sand once again. When its useful life is done, a cordwood home will biodegrade better than most, particularly when one of the greener binder options is used, discussed below. But, given protection and good build quality, a cordwood home will last a long time indeed, a hundred years or forever, whichever comes first. "Protection," incidentally, comes from keeping the cordwood masonry off the ground and guarding the walls against constant dampness by employing a decent roof overhang.

Low embodied energy. Classic cordwood masonry walls have three material components: the log-ends, the mortar matrix and the insulated cavity within the mortar. Let's see how these components measure up on embodied energy.

The cordwood measures up very well indeed if it is local. If you haul the cordwood in on a flatbed truck from 1500 miles away, well, there's a lot of fossil fuel that goes into haulage, so a good part of cordwood's advantage in this would be lost. Use local woods, maybe even trees that you need to clear for the building site. The other embodied energy in the cordwood itself is the energy required to cut the trees into short log-ends. Typically, this is done with a chainsaw, so gas and oil are consumed, but not a great amount for the quantity of building material you get out of the process. Cordwood can also be cut with a large diameter crosscut saw (buzzsaw) powered by the power takeoff (PTO) from a tractor, or by a gas or electric motor. This type of saw can cut a lot of wood quickly - and accurately - with a minimal amount of fossil fuel.

The mortar matrix is what binds the wall together and gives cordwood masonry its pleasing textural appearance. It is also a key element in the energy-efficiency, to be discussed next. Your question implies that we are using a lot of Portland or masonry cement in the mortar, but I don't think it's all that much, and (for the real purists) there are alternatives to a Portland-based mortars, as we will see.

I am not a religious purist with regard to green building. I also drive a car to get from A to B, and even get on a plane if I have to go as far as C. In 59 years on this planet, I have learned very little, if anything, that I would categorize as "absolute truth." But these come close: (1) Everybody's different. (2) Be wary of dogmatism, because truth - thanks to (1) - is both personal and transient (3) Embrace tolerance. This one is, perhaps, a logical corollary of (1) and (2). And, finally, I like this one from my father: (4) Exercise moderation in all things. You can have too much of almost anything: water, food, money, even purity of ideals.

So I use Portland cement in the mortar, a material that uses a lot of embodied energy in its manufacture and transport. But I use it in moderation. My Portland-based mortar recipe is 9 sand, 3 soaked sawdust, 2 Portland , and 3 hydrated lime, the amounts being equal parts (shovelfuls) by volume. With a standard pointy-ended spade, and consistent medium-sized shovelfuls, this recipe yields a wheelbarrow load of mortar, sufficient to lay up 2 SF of 16" thick cordwood masonry wall. As I get 12 shovelfuls out of a standard 94-pound bag, I can do 12 SF of 16" cordwood masonry from a bag. A house of 960 SF of external wall, then, will require 32 bags of Portland cement, not a huge amount, and a whole lot less than the amount used in concrete foundations. Using smaller mortar joints and a narrower wall, I still marvel that Jaki and I did the cordwood masonry at Log End Cottage in 1975 with just 6 bags of Portland .

Lately, we have had good success with using lime putty mortar, with no Portland at all. This is very similar to mortar as it was made before 1824. A Brit living near Portland , England discovered the manufacturing process of what is now called " Portland " cement about that time, apparently through experimentation in his kitchen! Lime putty mortar has lots of advantages, not the least of which is that it contains very much less embodied energy than the cement variety. (This is too big a subject for this piece. Interested readers should consult a detailed article about Lime Putty Mortar that I did for the Collected Papers of the 2005 Continental Cordwood Conference, available from BackHome and Earthwood Building School )

But, greenwise, it can get even better. Quite a few cordwood builders in the past five years have been doing cordwood masonry with cob as the binding matrix, instead of mortar. We even did some of this at Earthwood Building School when the famous cobbers Ianto Evans and Linda Smiley (Cob Cottage Company) came to visit. It worked well, but is not sustainable for us, as there is no good source of clay nearby. But for anyone with accessible clay as an indigenous material - probably half the country, I'm guessing - then cob is a viable alternative. Cob's constituent ingredients are: clay (about 20% by volume, if the clay is fairly pure), sand and (for use with cordwood) chopped straw as reinforcing binder. The clay is the "cement" of cob and sand is where the strength and hardness come from, so coarse sand is okay. The straw ties the matrix together, much like the polypropylene fibers in reinforced concrete. This type of cordwood masonry is sometimes known as "cobwood" and is very popular with green building purists.

For insulation, we use sawdust, a waste product from sawmills. It has an insulative value of about R-3 per inch. The insulation cavity of a 16" cordwood wall, then, has an R-value between R-18 and R-24. We treat the sawdust with hydrated lime as a preservative, one part of lime mixed in with 12 parts of sawdust. We recently put a doorway through a 25-year-old exterior cordwood wall, and we were able to salvage and reuse both the cordwood and the insulation on a new cordwood wall. In short, cordwood insulation is the greenest kind I know.

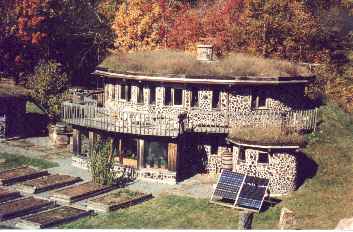

Energy-efficiency. It's hard to call a building green which uses a lot of energy for heating and cooling. Thanks to the thick log-end walls and the wonderful juxtaposition of insulation and thermal mass (the mortar matrix) in cordwood masonry, cordwood homes are very energy-efficient. Moreover, they maintain a steady and comfortable temperature, summer and winter. We use about 3.5 full cords of wood to heat the 2400 SF of living space. And that's usable square feet. Using exterior dimensions, the place is over 2800 SF. Burning hardwood slabs - a waste product from our local sawmill - through our masonry stove, we spend an average of $300 a year on fuel, and nothing on air-conditioning. (In complete fairness, I have to say that the round shape and the earth-sheltered feature of the home contribute to the home's energy efficiency, too, but the cordwood masonry is a big part of it.)

The healthy home. Cordwood masonry is inert. There is no off-gassing, outside of normal wood aroma, not unpleasant anyway (with the exception of certain elms, which I would not use anyway.) Lime and Portland mortars can cause skin damage when they are fresh, so we always use cloth-lined rubber gloves during the building process, and insist upon this with our students. But, once it has cured, the mortar presents no more of a health hazard than, say, limestone. We rarely use any coating on log-ends, and never any chemical preservative. I have occasionally used two or three coats of water-based urethane on certain special feature log-ends.

Is cordwood masonry green? Well, in this author's admittedly biased opinion, it compares very favorably with any other building method.

- - - - - - - - - - - - -

Rob Roy has written and contributed to several books about cordwood masonry, including Cordwood Building : The State of the Art. With his wife, Jaki, he has taught cordwood masonry at Earthwood Building School in West Chazy , NY since 1981. Contact Earthwood at 518-493-7744 or go to their website at www.cordwoodmasonry.com

For Email contact go to About Us

Established in 2001, GreenHomeBuilding.com is primarily a labor of love. Kelly, and the GreenHomeBuilding team of experts, have answered thousands of questions for readers over the years, and we continue to publish up-to-date information about increasingly important sustainable architecture. If you feel moved to assist us in this work, your kind donation would be much appreciated; this can be easily done through our PayPal account:

VISIT OUR OTHER WEBSITES:

[Natural Building Blog] [Earthbag Building] [Dream Green Homes]

Disclaimer Of Liability And Warranty

I specifically disclaim any warranty, either expressed or implied, concerning the information on these pages. Neither I nor any of the advisor/consultants associated with this site will have liability for loss, damage, or injury, resulting from the use of any information found on this, or any other page at this site. Kelly Hart, Hartworks LLC.